Application Overview

Dry Mortar

Plasters, tile adhesives, filling compounds, joint fillers, adhesive and reinforcing compounds (thermal insulation composite systems)

Advantages of products with Celofiber®

- Better rheology and processing properties

- Improved slump resistance

- Suppressed formation of cracks and pinholes during drying and setting

- Reduced tool sticking

Additional benefits in tile adhesives:

- Extended open time

Bitumen Products

roof coatings, expansion bands, paintable and brush-applied bitumen compounds, sound damping sheets (automotive)

Advantages of products with Celofiber®

- Better rheology and processing properties

- Highly efficient thickening effect

- Better thermal stability (>90°C)

- A better alternative - ecologically and healthwise (i.e. for asbestos)

Additional benefits in paintable and brush-applied compounds:

- Provides thicker coats to be applied in one process

- Reduced running down from vertical walls

Polyurethane

polyurethane manufacture in wet process

Main advantages when processing with Celofiber®

· Capillary provider during manufacturing process

· Improvement of steam permeability.

· Improvement of mechanical stability

· Enhancement of leather-like character

Welding Electrodes

Welding with pencil electrodes is still one of the most low-cost methods in structural steel work. Electrodes with a high ratio of Celofiber® are mainly used for welding work in constrained positions.

Main advantages when processing with Celofiber®

- Passivation of welding seam

- Good quality of welding seam in constrained positions

Celofiber in Drymix Mortar Industry

Tile adhesive

Recommended dosage: 0.3%-0.5%

Recommended type: Celofiber CF300W, Celofiber CF500W

Advantage:

Better workability

Better standability

Longer open time

Skim coat, spackling

Recommended dosage: 0.3%-1.0%

Recommended type: Celofiber CF200W, Celofiber CF300W

Advantage:

Crack resistance

Reduce shrinking

Better rheology

Tile grout, joint filler

Recommended dosage:0.3%-0.4%

Recommended type: Celofiber CF60W, CF300W

Advantage:

Less shrinkage

Reduce cracking

Joint compound, joint filler for gypsum

Recommended type: Celofiber CF300W

Recommended dosage:0.3% - 0.4%

Advantage:

Less shrinkage

Better workability

Better standability

Prevent cracking

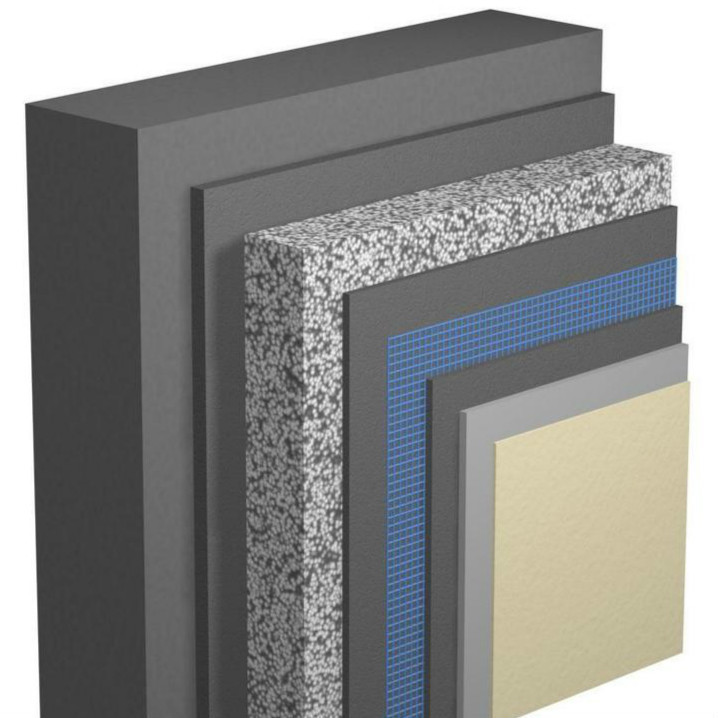

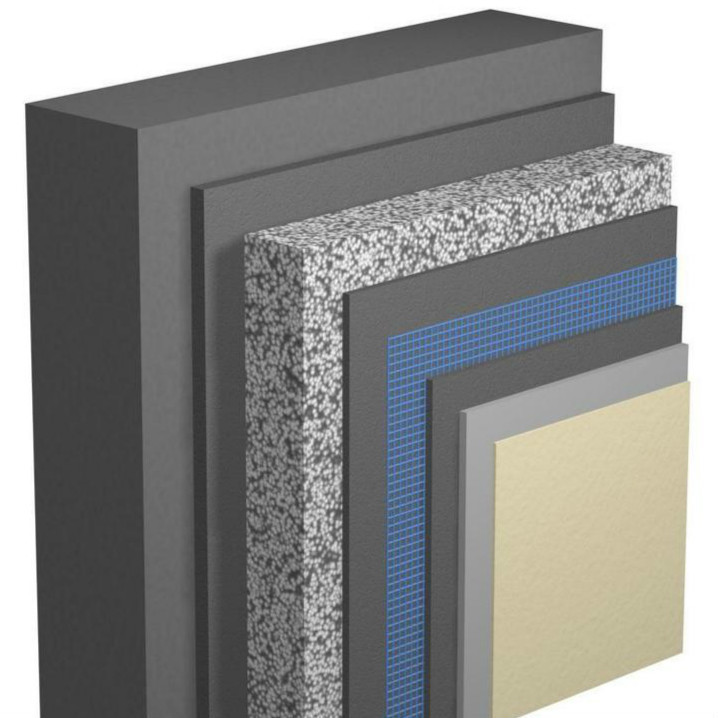

Insulation mortar

Recommended dosage: 0.3% - 0.4%

Recommended grades: Celofiber CF500W, CF450G, CF750G

Advantage:

Reduce cost

Improved workability

Better standability

Wall putty

Recommended dosage: 0.3% - 0.4%

Recommended grades: Celofiber CF60W, CF200W, CF300W

Advantage:

Crack resistance

Reduced shrinking

Improved workability

Better grindability

Finishing Texture coating

Recommended dosage: 0.2% - 0.4% for exterior

Recommended dosage: 0.5-2.0% for interior

Recommended grades: Celofiber CF500W

Advantage:

Crack resistance

Better structuring

Better standability

Better rheology

Need Help?

Please leave your name and mail address, we will contact with you soon!

Tag: Cellulose fiber, celofiber,anti-creacking agent,celotech,drymix mortar,tile adhesive,plaster,anti-sagging,anti-slip

Celotech Chemical | Drymix Info | Cemotech | China Drymix Mortar Association | China Drymix Mortar | Celotech