Natural Upgrade

Celofiber Technology is a branch and business unit of Celotech Chemical Group. Celofiber is concentrating on developing, producing and marketing of cellulose fiber products to several industries.

Celofiber in Drymix Mortar Industry

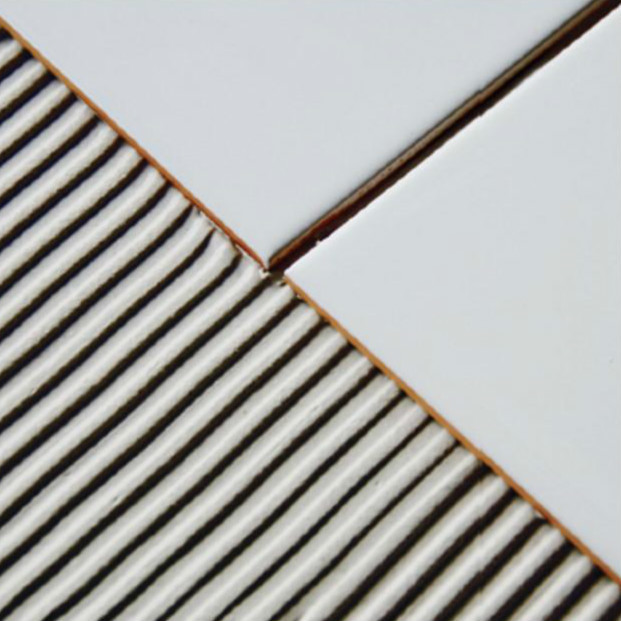

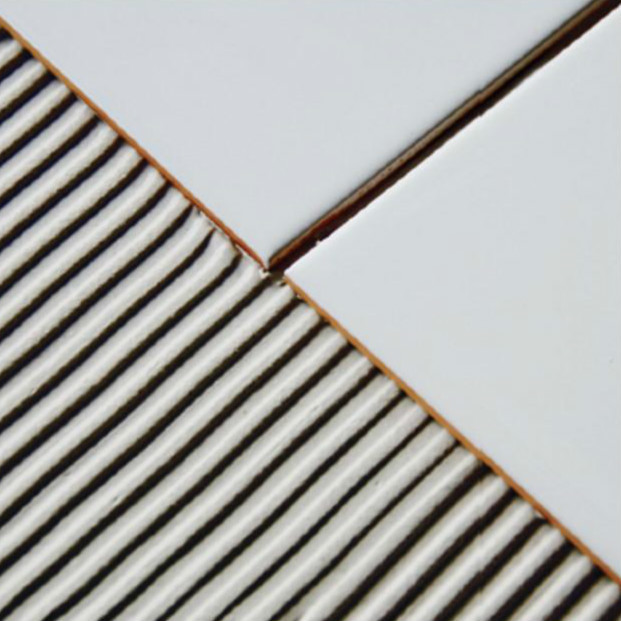

Tile adhesive

Recommended dosage: 0.3%-0.5%

Recommended type: Celofiber CF300W, Celofiber CF500W

Advantage:

Better workability

Better standability

Longer open time

Skim coat, spackling

Recommended dosage: 0.3%-1.0%

Recommended type: Celofiber CF200W, Celofiber CF300W

Advantage:

Crack resistance

Reduce shrinking

Better rheology

Tile grout, joint filler

Recommended dosage:0.3%-0.4%

Recommended type: Celofiber CF60W, CF300W

Advantage:

Less shrinkage

Reduce cracking

Joint compound, joint filler for gypsum

Recommended type: Celofiber CF300W

Recommended dosage:0.3% - 0.4%

Advantage:

Less shrinkage

Better workability

Better standability

Prevent cracking

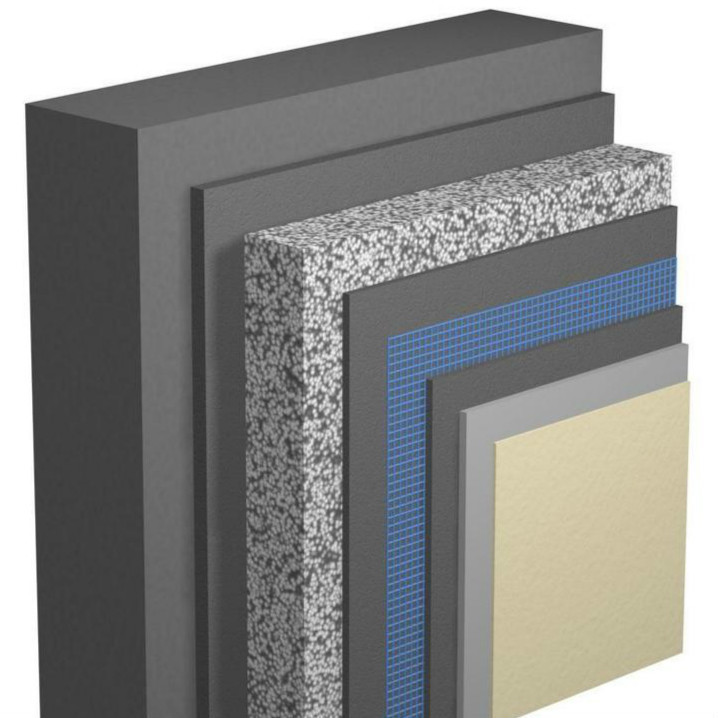

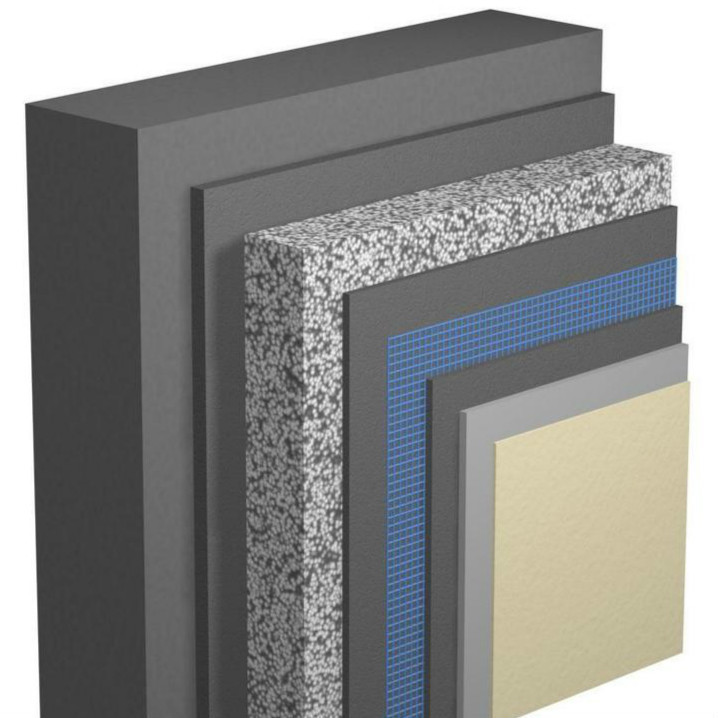

Insulation mortar

Recommended dosage: 0.3% - 0.4%

Recommended grades: Celofiber CF500W, CF450G, CF750G

Advantage:

Reduce cost

Improved workability

Better standability

Wall putty

Recommended dosage: 0.3% - 0.4%

Recommended grades: Celofiber CF60W, CF200W, CF300W

Advantage:

Crack resistance

Reduced shrinking

Improved workability

Better grindability

Finishing Texture coating

Recommended dosage: 0.2% - 0.4% for exterior

Recommended dosage: 0.5-2.0% for interior

Recommended grades: Celofiber CF500W

Advantage:

Crack resistance

Better structuring

Better standability

Better rheology

Application Overview

Dry Mortar

Plasters, tile adhesives, filling compounds, joint fillers, adhesive and reinforcing compounds (thermal insulation composite systems)

Advantages of products with Celofiber®

- Better rheology and processing properties

- Improved slump resistance

- Suppressed formation of cracks and pinholes during drying and setting

- Reduced tool sticking

Additional benefits in tile adhesives:

- Extended open time

Bitumen Products

roof coatings, expansion bands, paintable and brush-applied bitumen compounds, sound damping sheets (automotive)

Advantages of products with Celofiber®

- Better rheology and processing properties

- Highly efficient thickening effect

- Better thermal stability (>90°C)

- A better alternative - ecologically and healthwise (i.e. for asbestos)

Additional benefits in paintable and brush-applied compounds:

- Provides thicker coats to be applied in one process

- Reduced running down from vertical walls

Polyurethane

polyurethane manufacture in wet process

Main advantages when processing with Celofiber®

· Capillary provider during manufacturing process

· Improvement of steam permeability.

· Improvement of mechanical stability

· Enhancement of leather-like character

Welding Electrodes

Innovative Functional Additives for Efficient and High-quality Production of Welding Electrodes

Welding with pencil electrodes is still one of the most low-cost methods in structural steel work. Electrodes with a high ratio of Celofiber® are mainly used for welding work in constrained positions.

Main advantages when processing with Celofiber®

- Passivation of welding seam

- Good quality of welding seam in constrained positions

Need Help?

Please leave your name and mail address, we will contact with you soon!

Applications

Drymix Mortar

Welding Electordes

Concrete

Filtration

Filling

Tag: Cellulose fiber, celofiber,anti-creacking agent,celotech,drymix mortar,tile adhesive,plaster,anti-sagging,anti-slip

Celotech Chemical | Drymix Info | Cemotech | China Drymix Mortar Association | China Drymix Mortar | Celotech